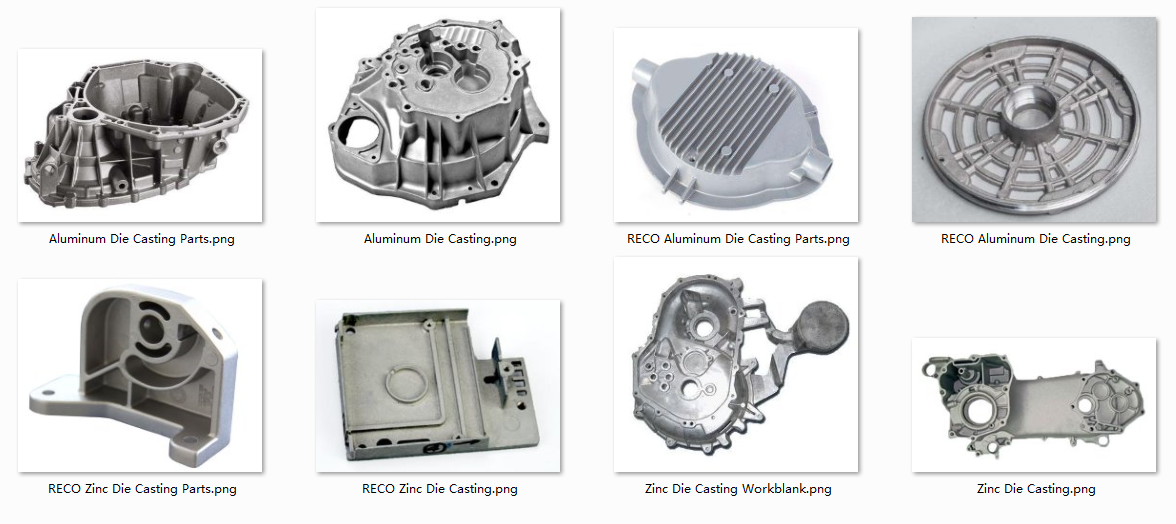

Die Casting

Die Casting, is the method of making liquid or semi-liquid metal fill the die-casting mold cavity at a relatively high speed under high pressure, and form and solidify under pressure to obtain a casting parts

The main characteristics of die casting is a metal mold filling under high pressure, high speed, and forming and solidification under high pressure, the deficiency of die casting is: because the liquid metal under high pressure, high speed of mold filling process, inevitably, the clip wrapped inside the casting, the air in the cavity formed subcutaneous blowhole, so you should not heat treatment, aluminum alloy die casting zinc alloy die casting is unfavorable surface coating (but can spray paint).

Otherwise, when the air holes in the casting are heated, they will expand and cause casting deformation or bubble.In addition, the machining allowance of die casting should be small, generally around 0.5mm, which can not only reduce the weight of the casting, reduce the amount of machining to reduce the cost, but also avoid penetrating the surface dense layer, exposing the subcutaneous pores, resulting in workpiece scrap..

Service

Contact Us

Name: Kevin Hu

Tel: +86-18026978395

E-mail: [email protected]

Skype: recometaltech

WeChat: RECOMETALTECH

Whatsapp: +86 180 2697 8395

Add: Datianyang Industrial Zone,Songgang Street, Baoan District, Shenzhen,China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry